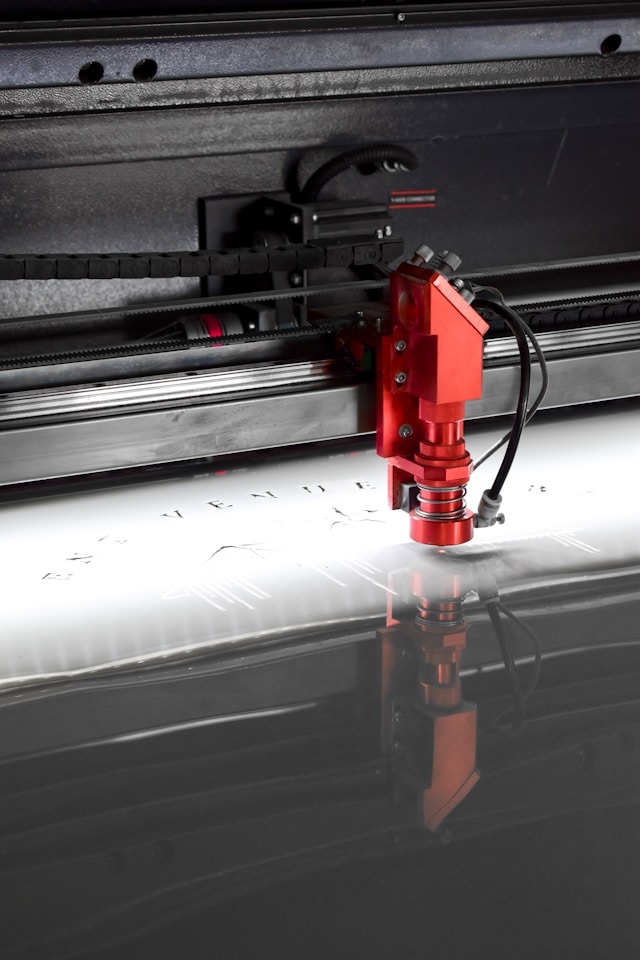

Laser cutting is a highly advanced and versatile manufacturing process that utilizes a focused laser beam to precisely cut, engrave, or etch materials with unparalleled accuracy and efficiency. This innovative technology has revolutionized various industries, including manufacturing, aerospace, automotive, electronics, and medical, by offering a cost-effective and precise method for producing intricate designs, complex shapes, and custom components.

At its core, spectrum laser cutting involves the use of a high-powered laser beam generated by a laser cutting machine. The laser beam is focused through a series of mirrors and lenses onto the surface of the material to be cut or engraved. Depending on the specific application and material properties, the laser beam can be adjusted in intensity, speed, and focus to achieve optimal cutting results. One of the primary advantages of laser cutting is its exceptional precision and accuracy. Unlike traditional cutting methods such as sawing or milling, which rely on physical contact with the material, laser cutting produces clean, sharp edges with minimal distortion or burrs. This level of precision allows for the creation of intricate designs, fine details, and complex geometries that would be difficult or impossible to achieve using conventional cutting techniques.

Furthermore, laser cutting offers unparalleled versatility and flexibility in terms of the materials that can be processed. While laser cutting is commonly used with materials such as metal, plastic, wood, and acrylic, it can also be used to cut a wide range of other materials, including glass, ceramics, rubber, fabric, and composite materials. This versatility makes laser cutting ideal for a diverse array of applications across various industries.

Another key benefit of laser cutting is its high level of automation and efficiency. Laser cutting machines are equipped with computer numerical control (CNC) systems that allow for precise control and programming of cutting parameters, such as cutting speed, power, and path. This level of automation enables rapid prototyping, batch production, and mass customization of parts and components with minimal human intervention, reducing production time and costs.

Moreover, laser cutting offers exceptional speed and productivity compared to traditional cutting methods. The high-powered laser beam can cut through materials with remarkable speed and efficiency, allowing for rapid production of parts and components. Additionally, laser-cutting machines can operate continuously without the need for tool changes or downtime, further enhancing productivity and throughput.

In addition to cutting, laser technology can also be used for engraving, etching, and marking various materials. Laser engraving involves removing material from the surface of a material to create designs, logos, or text, while laser etching involves creating shallow grooves or patterns on the surface of a material. Laser marking, on the other hand, involves changing the colour or composition of a material’s surface to create permanent marks or identifiers.

One of the most significant advancements in laser-cutting technology in recent years is the development of fibre laser-cutting machines. Fiber lasers utilize a solid-state laser source, typically made from rare-earth elements such as ytterbium, erbium, or neodymium, to generate a laser beam. These fibre lasers offer several advantages over traditional CO2 lasers, including higher cutting speeds, improved energy efficiency, and greater reliability.